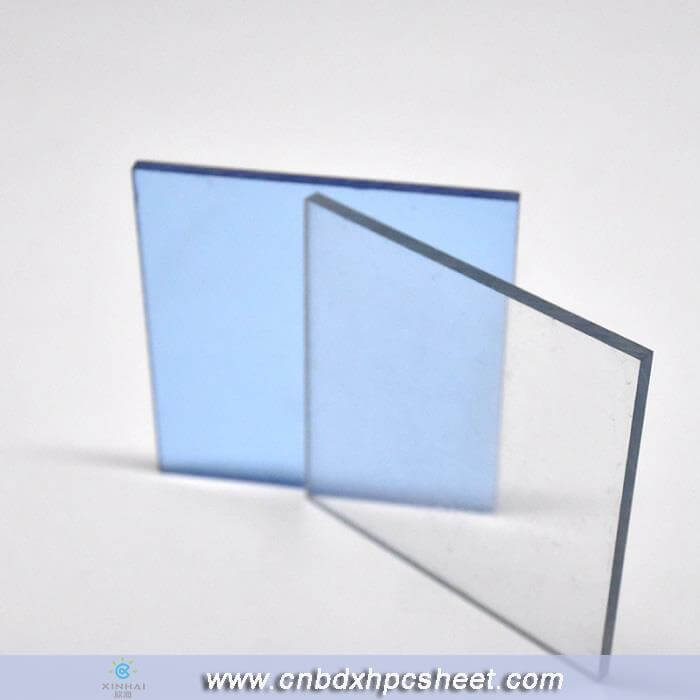

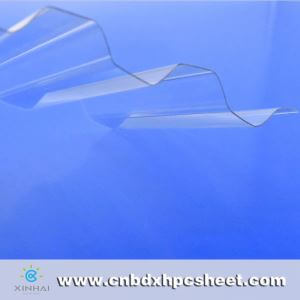

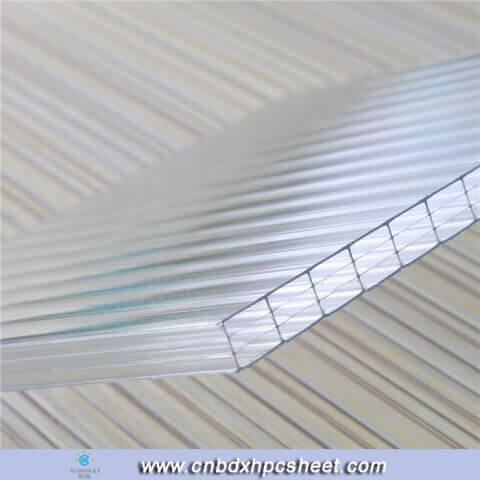

Transparent Roof Sheets Polycarbonate Panel

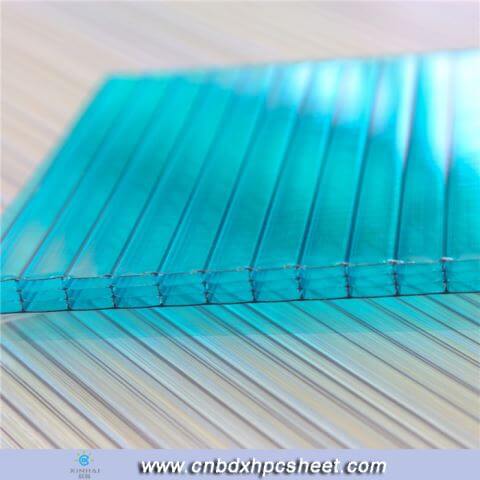

Polycarboante sheet has incomparable lightweight compared with other lighting material at the same thickness, it can save more steel skeleton material and also has excellent resistance to wind pressure and snow loading compared with other lighting covering material. Product detail Product...

Product Details

Polycarboante sheet has incomparable lightweight compared with other lighting material at the same thickness, it can save more steel skeleton material and also has excellent resistance to wind pressure and snow loading compared with other lighting covering material.

Product detail

|

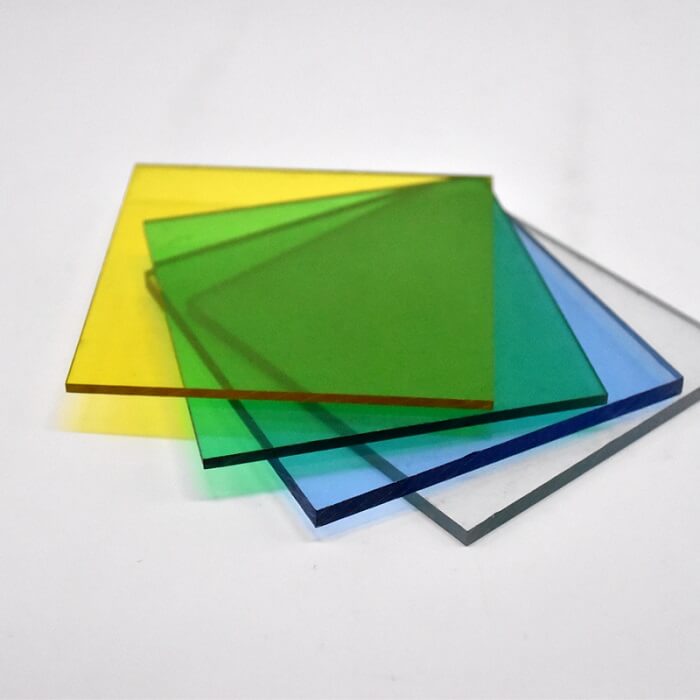

Color: |

Clear, green, blue , brown , opal ,clear or as per request |

|

Material: |

100% bayer material or sabic material or customized |

|

Maximum width: |

2200mm,Customizable |

|

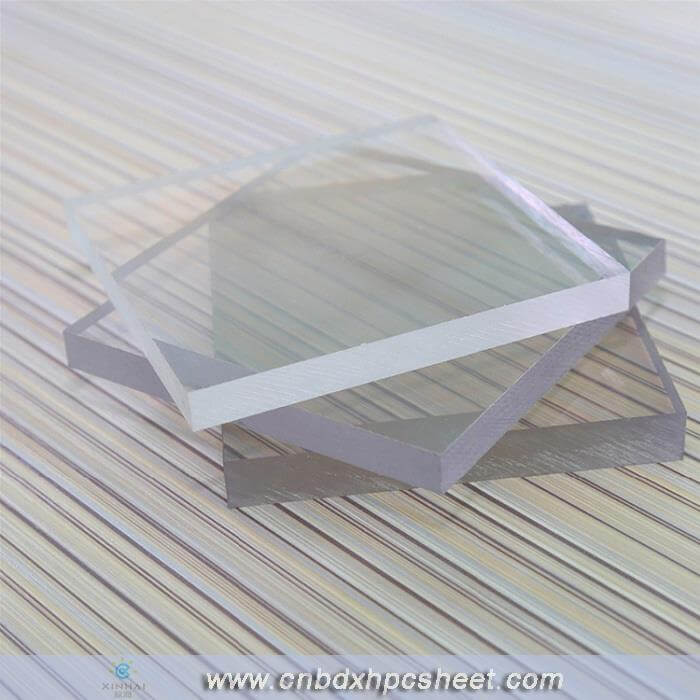

Thickness: |

1.2mm-18mm |

|

Length: |

No limit,Customizable |

|

Certification: |

ISO 9001:2008 |

|

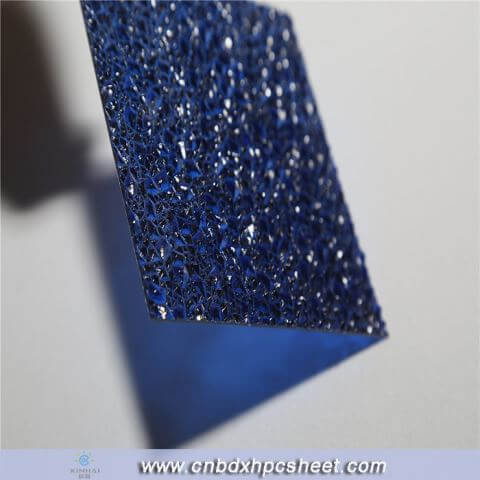

Surface: |

Anti-fog, UV protection |

|

UV thickness: |

50 micron,Franco |

|

Retardant standard: |

Grade B1(GB Standard) |

|

Technology: |

Co-extrusion |

|

Sample: |

Free sample could send you for test |

Product Pictures

Application

1.Industrial building industry workshop,warehouse,roof lighting.

2.Modern agricultural greenhouse,modern farms of agricultural facilities,green ecological restaurant,greenhouses.

3.Municipal construction daylighting corridor,carport,canopy,sound insulation screen waiting ares,kiosks,road,railway station,overpasses.

4.The daylighting of the sports venues,outdoor swimming pool,stadiums

5.Business application architecture decoration,stage design,exhibition layout,road signs,product display,advertising light boxes.

6.The adornment that occupy the home indoor and outdoor decoration,private residential lighting,indoor ceiling,indoor partition,shower enclosure,interior door and windows,sun room,block rain canopy,chimney.

7.Security facilities prison,bank,security counter,jewelry store,the museum security,anti-theft window police riot shields,industrial machinery,surgical shell.

Quality Control

1. Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

2. 100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels.

- <

- Previous: Panel Polycarbonate Plastic Greenhouse Roofing

- Next: Clear Polycarbonate Awning Canopy For Garden

- >