Polycarbonate Sheet 3mm Thickness

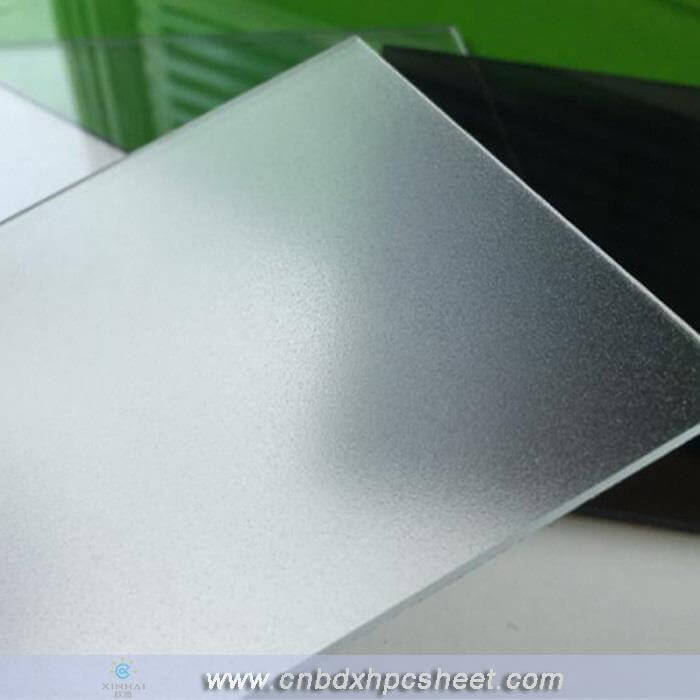

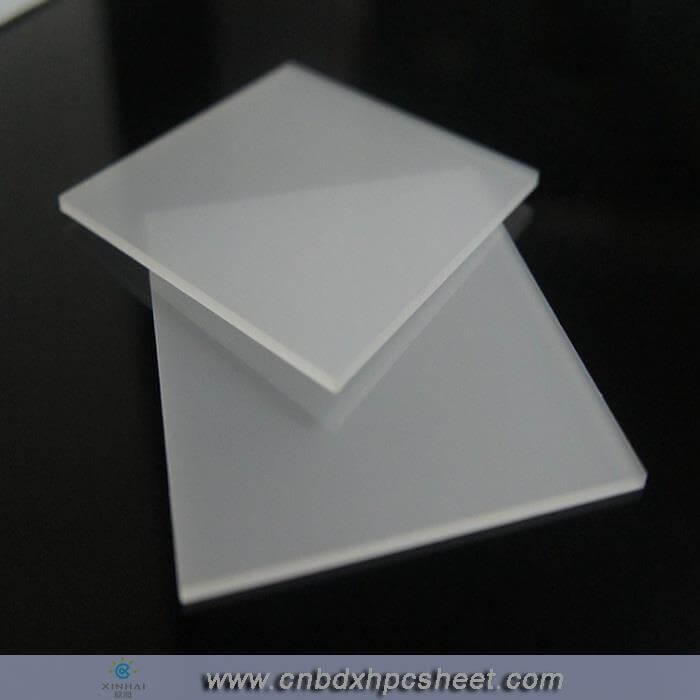

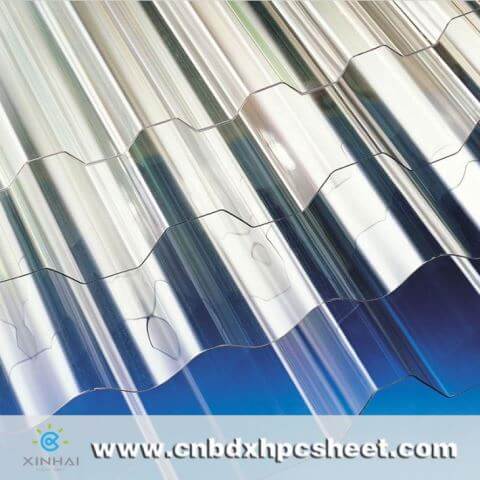

Standard specification All colors,size,material can be customized Photo of Frosted Polycarbonate Sheet Applications Stadium,industrial workshop,warehouse and public facilities the daylighting of the ceiling Sybway,station entrance-exit,corridors,walkways shading skylights. Parking,bicycle...

Product Details

Standard specification

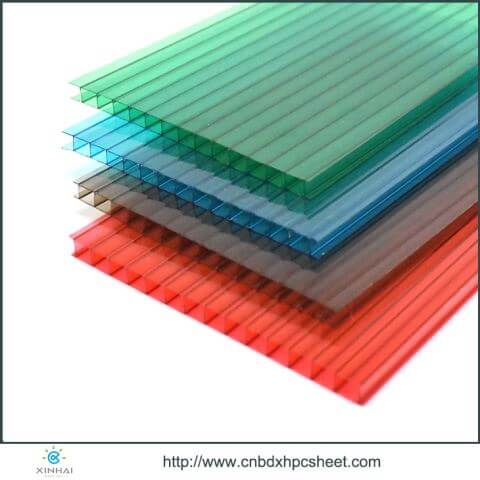

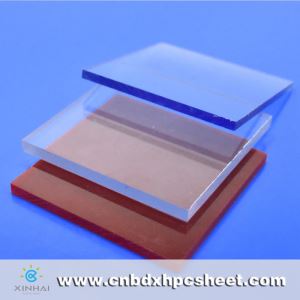

All colors,size,material can be customized

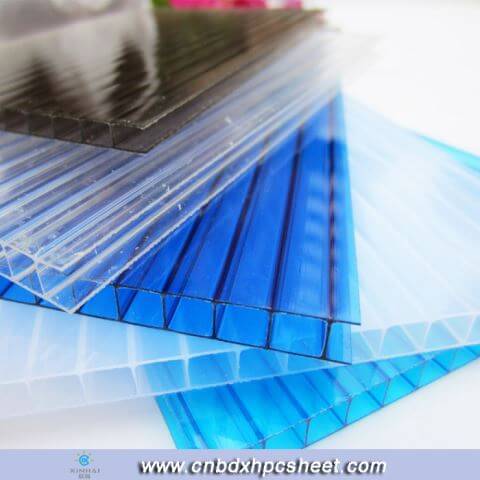

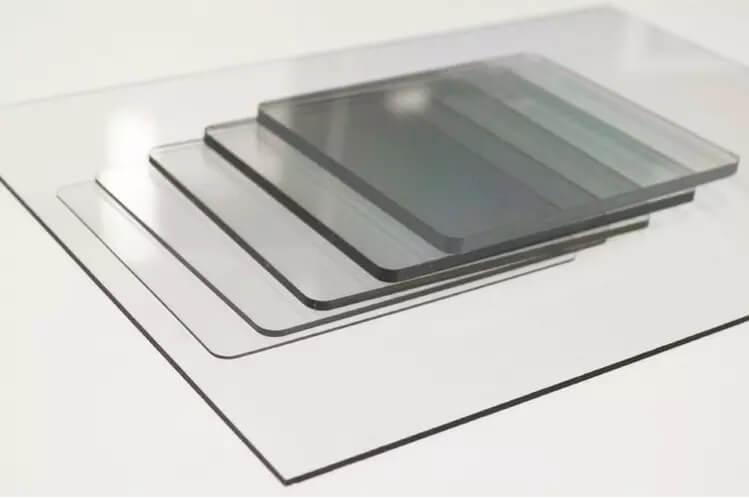

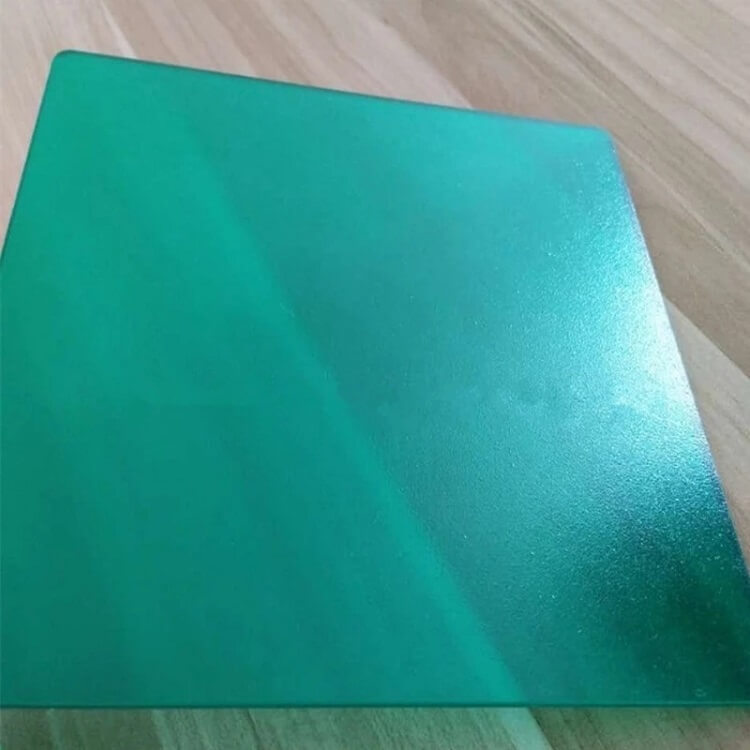

| Name: | PC frosted sheet |

| Material: | Polycarbonate resin |

| Color: | Clear, Opal, Lake blue, also could be custom color. |

| Width*Length: | 2.1*5.8 or customized |

| Thickness: | 2mm-8mm or other thickness |

| OEM: | Accept |

| Coating: | UV protection(One side or two sides). |

| Impact resistance: | 80 times that of glass, 15 times that of acrylic sheeting |

| Temperature resistance range | 40°~120° |

| Light weight | Only 1/12 of the weight of glass of the same thickness |

| Guarantee: | 10 years. |

| Delivery time: | 7-10 days once confirm your deposit. |

Photo of Frosted Polycarbonate Sheet

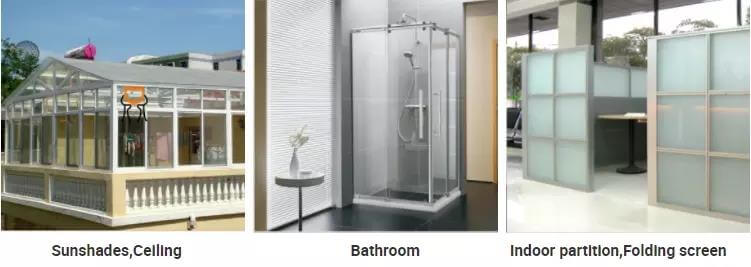

Applications

Stadium,industrial workshop,warehouse and public facilities the daylighting of the ceiling

Sybway,station entrance-exit,corridors,walkways shading skylights.

Parking,bicycle shed,home residential lighting storm canopy.

Agriculture greenhouse plant,green ecological restaurant,flower market and large exhibition greenhouse covering lighting.

Home courtyard sunlight greenhouse.

Packaging & Shipping

|

Package: |

Both sides with PE films, two ends with plastic tape. PE films for logo can be designs as customers' requirements |

|

Delivery time: |

Within 7~10 days after receiving your deposit |

|

Warrancy: |

Usually 10 year's quality guarantee which depends on the models you ordered. |

|

Product Size Length: |

Customized according to the requirement of customers |

|

Payment term: |

L/C, T/T,Western Union,Paypal,Cash |

| OEM Service: |

We can design and produce products based on your requirements |

FAQ

1.We are in very high temperature country, polycarbonate sheet can support?

A: Yes, Polycarbonate sheet Temperature Resistance can be: -40 ~ +120 degree centigrade

2.Do you take special orders ?

Yes , We accept customized products.

3. How to identify the UV side of the sheet?

A: The UV side is the side protected with the printed masking film. To avoid installing the sheet at the wrong side which will void the warranty, please ensure only to remove the masking film after the sheet has been installed.

4. How do I know that a polycarbonate sheet has UV layer?

A: You can’t see the UV layer with the naked eyes. A laboratory test is required to prove this. Some international labs have this facility. Usually UV side layer will more thicker than the down side.

- <

- Previous: Polycarbonate Roofing Sheets Cut To Size

- Next: Polycarbonate Glass Sheets

- >