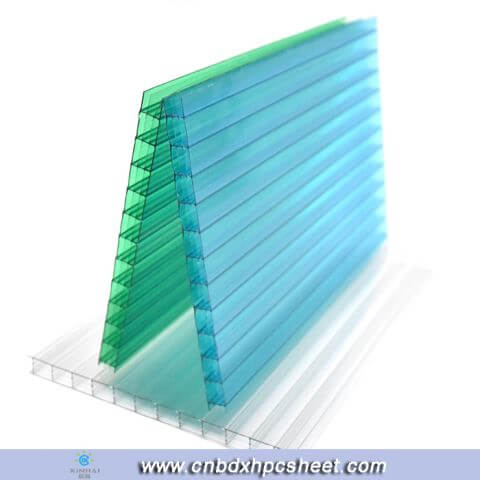

Polycarbonate Flat Roof Panels

Polycarbonate sheets are a transparent, synthetic product. Because of its exceptional impact, weather and temperature resistance, it provides solutions where other synthetics fail. Polycarbonate has a different chemical composition, and therefore different properties, from other transparent...

Product Details

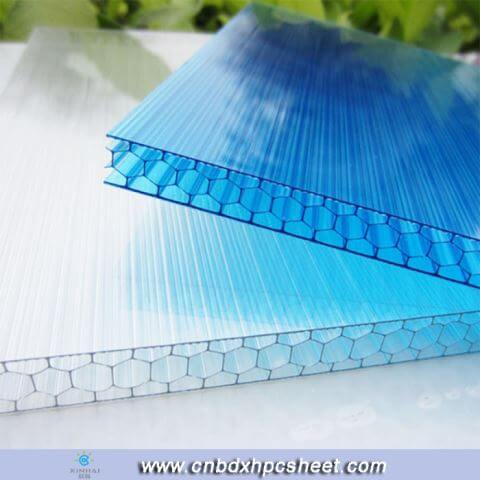

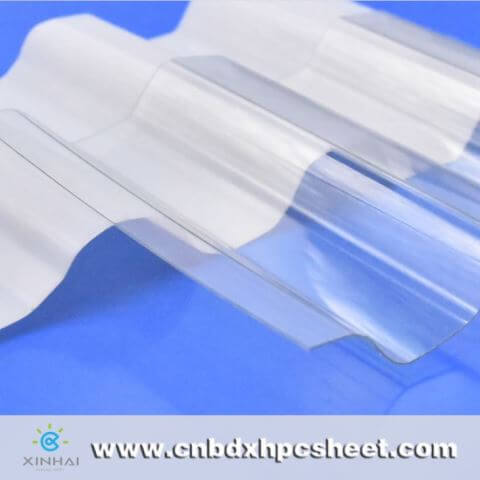

Polycarbonate sheets are a transparent, synthetic product. Because of its exceptional impact, weather and temperature resistance, it provides solutions where other synthetics fail. Polycarbonate has a different chemical composition, and therefore different properties, from other transparent plastics such as PVC.

Standard specification

All colors,size,material can be customized

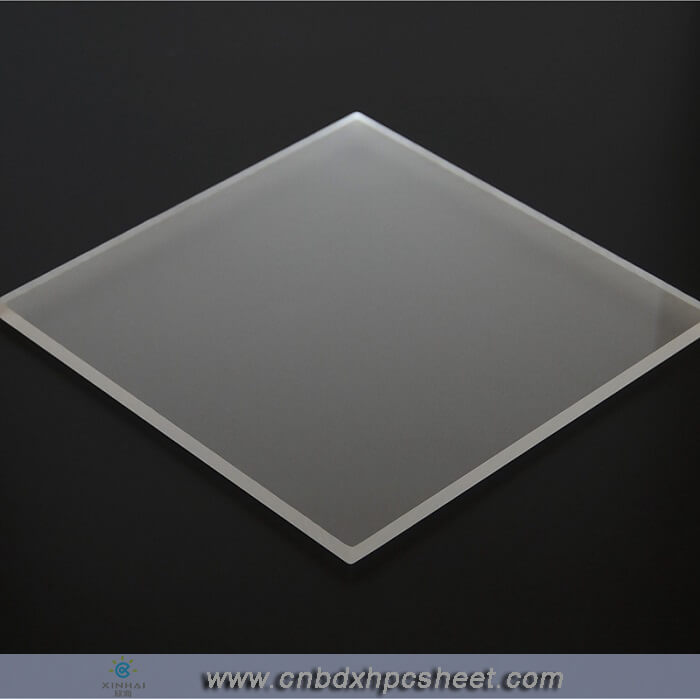

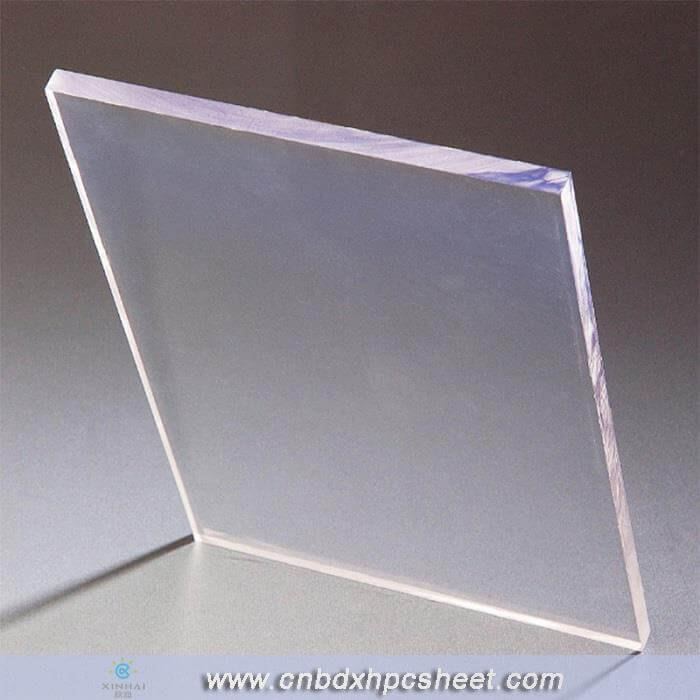

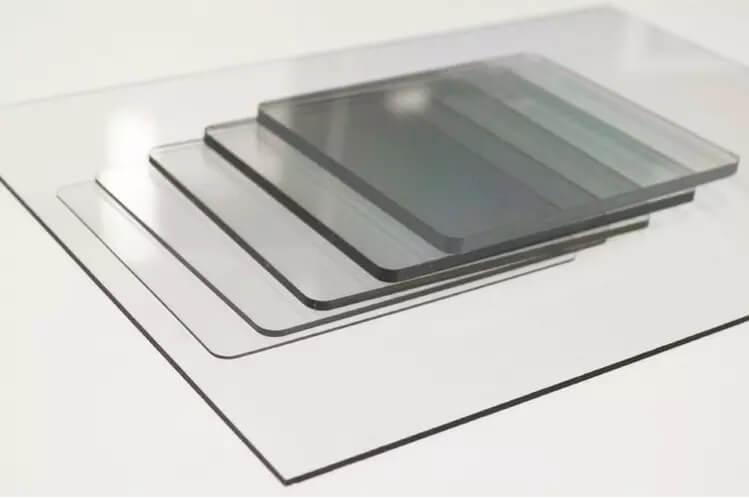

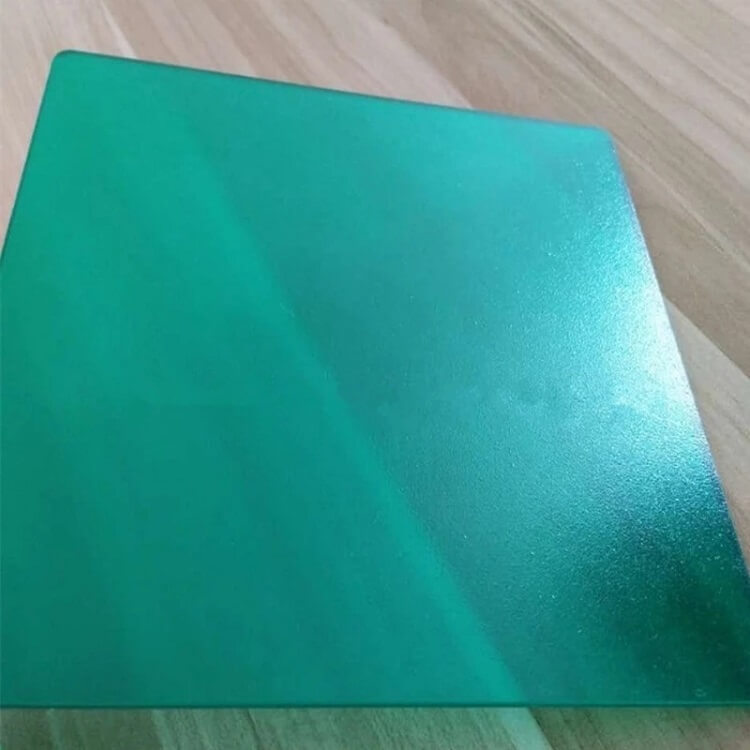

| Name: | PC frosted sheet |

| Material: | Polycarbonate resin |

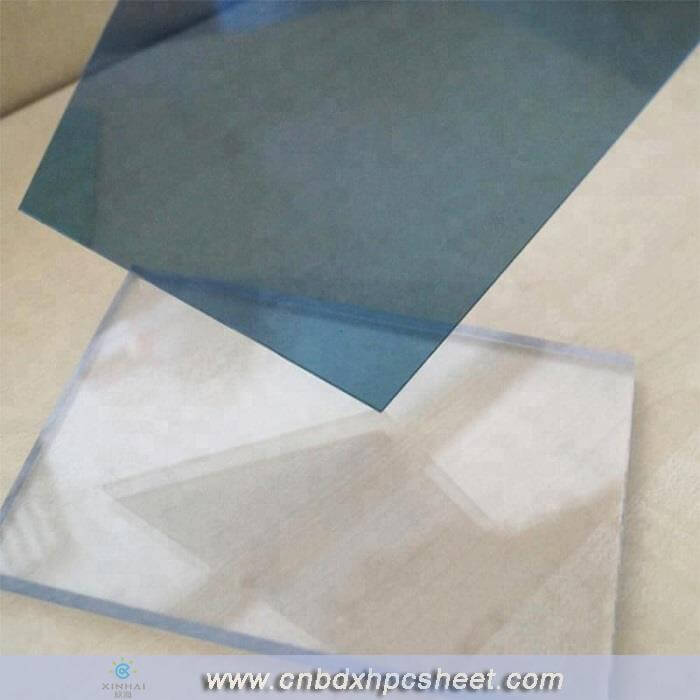

| Color: | Clear, Opal, Lake blue, also could be custom color. |

| Width*Length: | 2.1*5.8 or customized |

| Thickness: | 2mm-8mm or other thickness |

| OEM: | Accept |

| Coating: | UV protection(One side or two sides). |

| Impact resistance: | 80 times that of glass, 15 times that of acrylic sheeting |

| Temperature resistance range | 40°~120° |

| Light weight | Only 1/12 of the weight of glass of the same thickness |

| Guarantee: | 10 years. |

| Delivery time: | 7-10 days once confirm your deposit. |

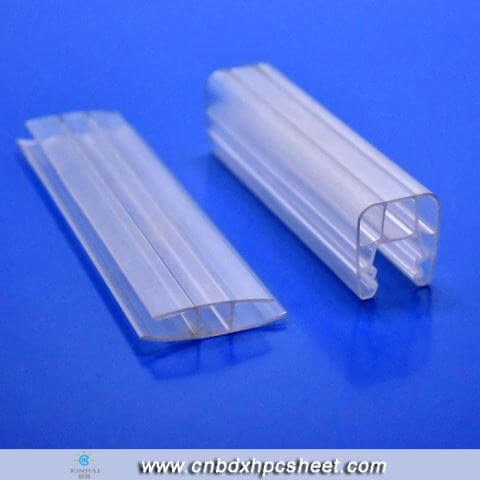

Photo of Frosted Polycarbonate Sheet

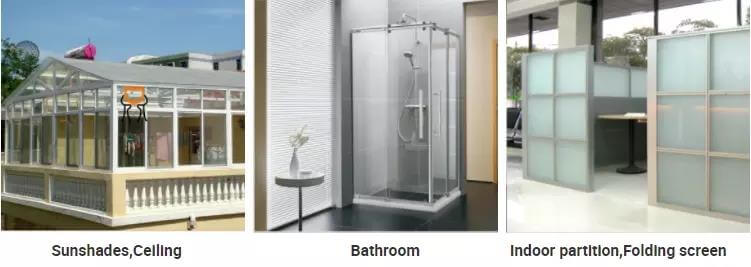

Applications

1. Building skylights

2. Indoor partition, Folding screen

3. Bathroom

4. Natatorium coverings

5. Market building

6. Architectural roofing

7. Roofing and glazing of industry

8. Walkways

9. Stadium roofing

Packaging & Shipping

|

Package: |

Both sides with PE films, two ends with plastic tape. PE films for logo can be designs as customers' requirements |

|

Delivery time: |

Within 7~10 days after receiving your deposit |

|

Warrancy: |

Usually 10 year's quality guarantee which depends on the models you ordered. |

|

Product Size Length: |

Customized according to the requirement of customers |

|

Payment term: |

L/C, T/T,Western Union,Paypal,Cash |

| OEM Service: |

We can design and produce products based on your requirements |

Quality Control

1. Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

2. 100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels

- <

- Previous: Cut To Size Polycarbonate Sheets

- Next: Poly Carbon Roof Sheet

- >