China Manufacturers Twin Wall Polycarbonate Sheet / Polycarbonate Plate

China manufacturers twin wall policarbonate sheet / polycarbonate plate Product Introduction Polycarbonate hollow sheet PC sheet light transmittance is as high as 89%, comparable to glass, free uv coating, no yellowing in the sun exposure, atomization.The impact strength is 250-300 times of...

Product Details

China manufacturers twin wall policarbonate sheet / polycarbonate plate

|

Product Name: |

China manufacturers twin wall policarbonate sheet / polycarbonate plate |

||

|

Material: |

100% bayer material or sabic material or customized |

||

|

Place Of Origin: |

Hebei,China |

||

|

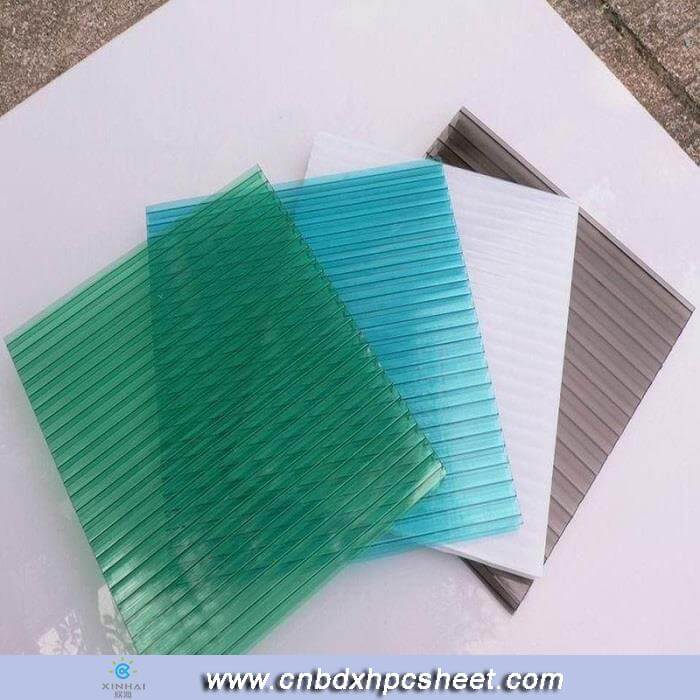

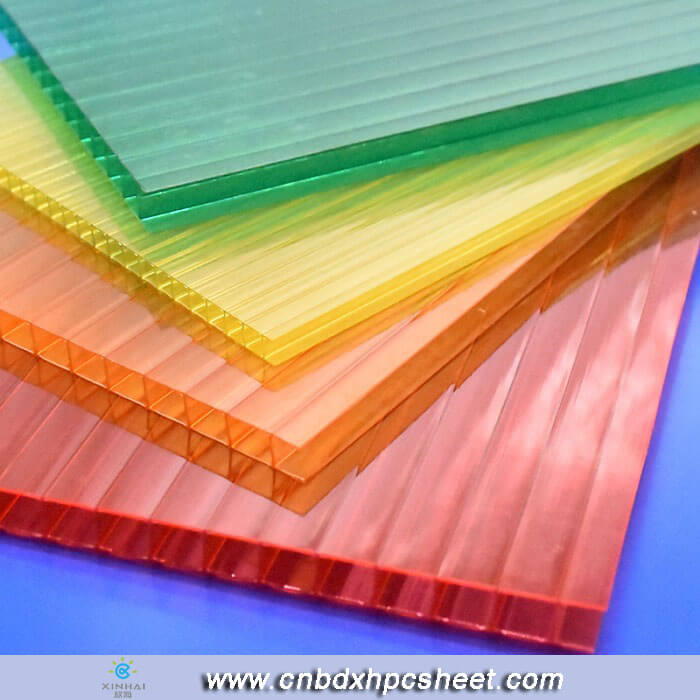

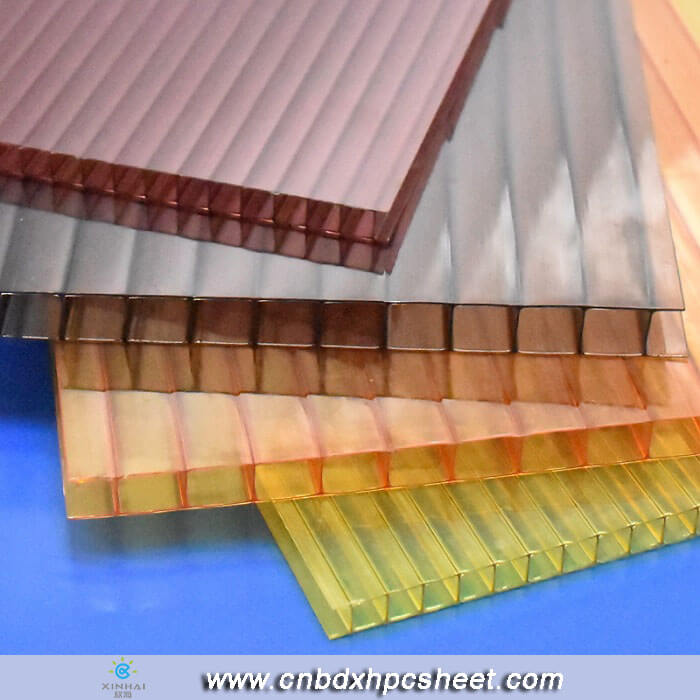

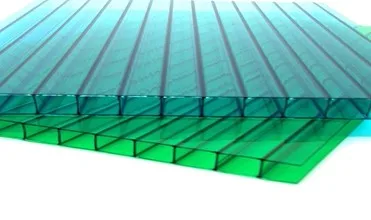

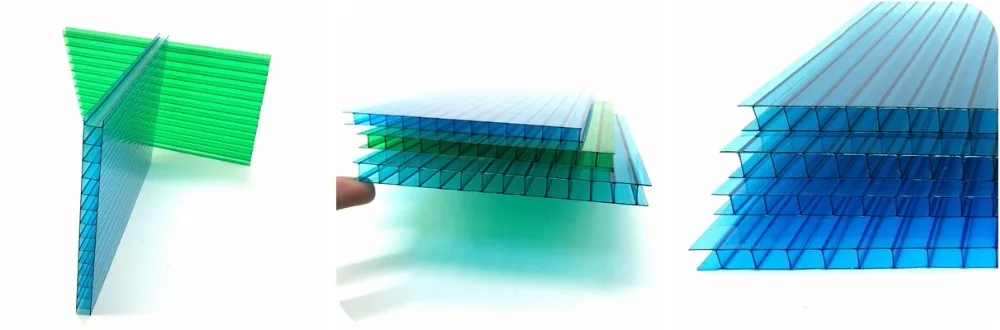

Color: |

Clear, Blue, Lake Blue,Green, Bronze, Opal or Customized |

||

|

Max Width: |

2170mm,Customizable |

||

|

Thickness: |

2.8mm-20mm,or as your request |

||

|

Length: |

Nnlimited,Customizable |

||

|

Certification: |

ISO 9001:2008 |

||

|

Surface: |

Anti-fog, UV protection |

||

|

UV Thickness: |

50 micron,Franco |

||

|

Retardant Standard: |

Grade B1(GB Standard) |

||

|

Autoignition Temperature: |

630℃ |

||

|

Technology: |

Co-extrusion |

||

|

Sample: |

Free sample could be sent to you for testing |

||

Product Introduction

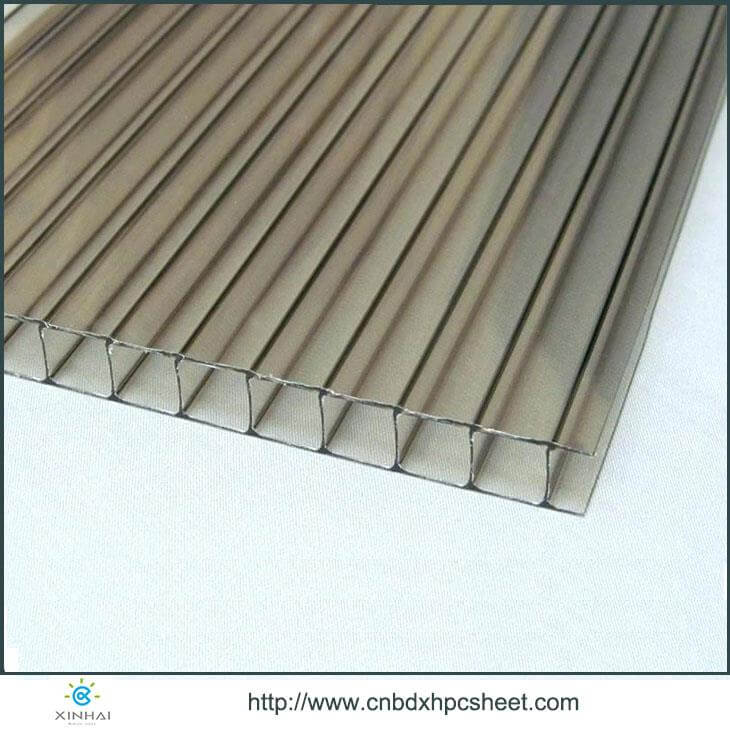

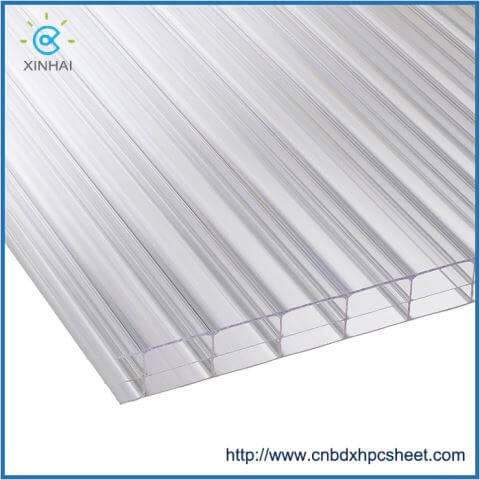

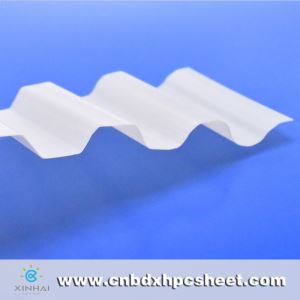

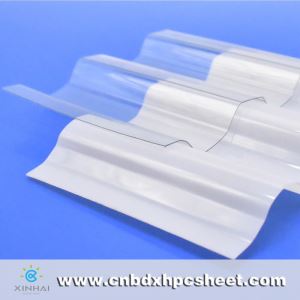

Polycarbonate hollow sheet

PC sheet light transmittance is as high as 89%, comparable to glass, free uv coating, no yellowing in the sun exposure, atomization.The impact strength is 250-300 times of ordinary glass, 30 times as thick as acrylic sheet.The proportion is only half of the glass, saving transportation, removing, installing and supporting the cost of the framework.PC board cold short does not occur when - 100 ℃, 135 ℃ when not soften.

The design drawing can be used in the construction site to adopt the cold bending method, the installation of arch, semicircle roof and window.The minimum bending radius is 175 times of the thickness of the plate.

|

Technical Data(twin wall polycarbonate hollow sheet) |

||

|

Characterics |

Unit |

Data |

|

Impact strength |

J/m |

2.1-2.3 |

|

Light transmission |

% |

88 |

|

Specify Gravity |

g/m |

1.2 |

|

Coefficient thermal expansion |

mm/m℃ |

0.065 |

|

Service temperature |

℃ |

-40℃~+120℃ |

|

Heat conductively |

W/m²℃ |

3.0-5.0 |

|

Flexural strength |

N/mm² |

100 |

|

Modulus of elasticity |

Mpa |

2400 |

|

Sound insulation effect |

db |

20 decibel decrease for 10mm pc sheet |

|

Tensile strength |

N/mm² |

≥60 |

Our Certificate

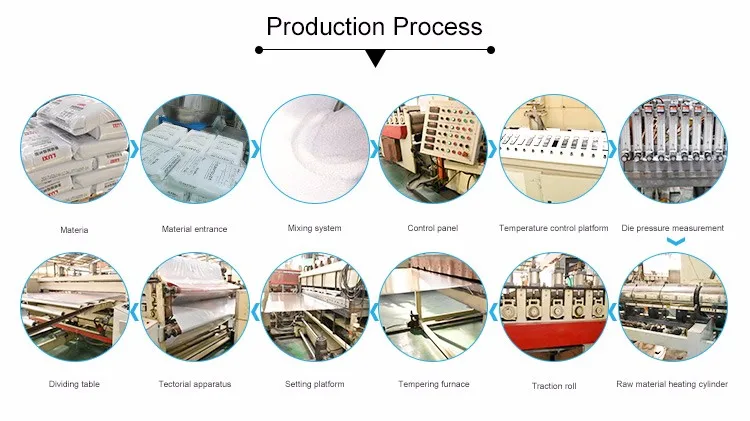

Product Processing

Product Packing

Our Company

Product Application

*1.Industrial building industry workshop,warehouse,roof lighting.

* 2.Modern agricultural greenhouse,modern farms of agricultural facilities,green ecological restaurant,greenhouses.

* 3.Municipal construction daylighting corridor,carport,canopy,sound insulation screen waiting ares,kiosks,road,railway station,overpasses.

* 4.The daylighting of the sports venues,outdoor swimming pool,stadiums

* 5.Business application architecture decoration,stage design,exhibition layout,road signs,product display,advertising light boxes.

* 6.The adornment that occupy the home indoor and outdoor decoration,private residential lighting,indoor ceiling,indoor partition,shower enclosure,interior door and windows,sun room,block rain canopy,chimney.

* 7.Security facilities prison,bank,security counter,jewelry store,the museum security,anti-theft window police riot shields,industrial machinery,surgical shell.

In order to avoid the negative impact caused by installation errors, Selecting XINHAI polycarbonate sheet,Give you the most accurate installation instructions to answer your questions at any time.

XINHAI polycarbonate sheet not only the quality of the sheet that is sold, but also the reputation of the factory.

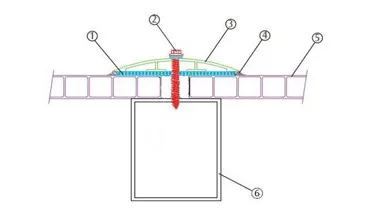

Simple installation drawing

①Waterproof tape

②Self-tapping screw

③Aluminum alloy pressure strip

④Neutral sealant

⑤Polycarbonate sheet

⑥Longitudinal keel

FAQ

Q1: What kind of a company you are ?

A: We are a manufacturer located Hebei, China .We have gained good reputation among our customers for our professional,warm and thoughtful service, Because we know that a long terms business based on the quality control,delivery time etc.

Q2: What's the quality assurance you provided and how do you control quality ?

A: 1)Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

2)100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels.

Q3: Can I install polycarbonate sheets myself ?

A: No problem.Polycarbonate sheets are particularly user-friendly and very light, so that fewer cross bars are needed.This makes the supporting structure more straight forward and cheaper.

Hot Sale Products

Chinese factory cheap price hard plastic pc sheet suppliers used swimming pool cover

greenhouse with polycarbonate sheet roofing for modern agriculture planting greenhouse full system

PC greenhouse high quality polycarbonate sheet 10 years warranty

Good price hollow polycarbonate sheet for plastic sunroof

- <

- Previous: Sell Polycarbonate Hollow Sheets,High Quality Polycarbonate Hollow Sheet,Lexan Polycarbonate Sheet,6mm Polycarbonate Sheet

- Next: UV Blocking Heating Protection Polycarbonate Hollow Sheet / Polycarbonate Panel

- >