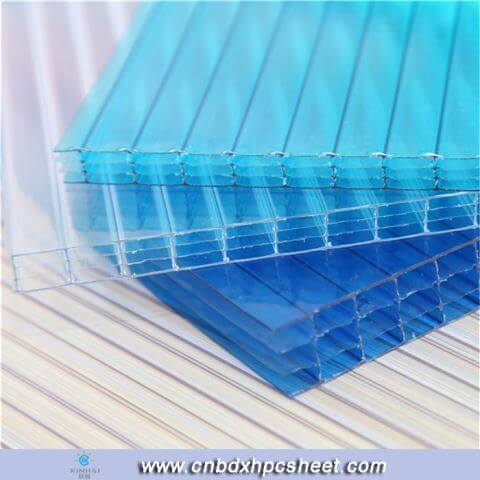

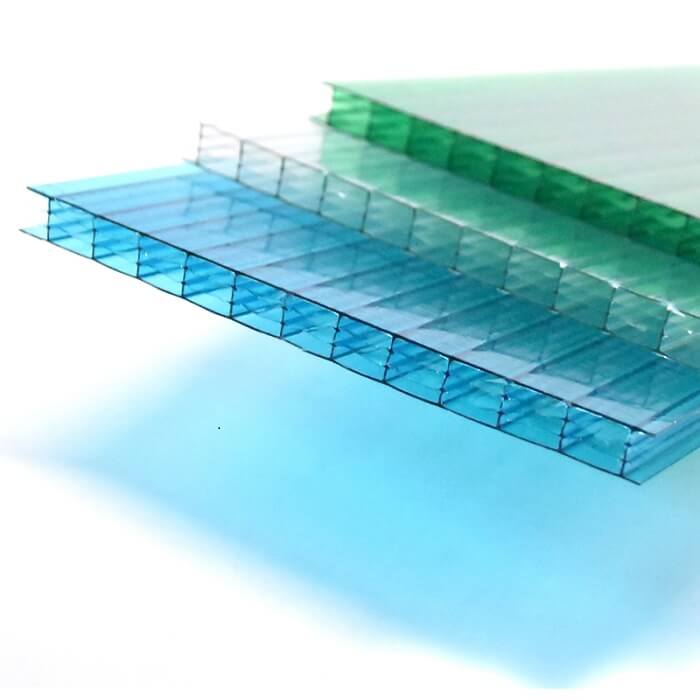

Clear Polycarbonate Roofing Panel

Product Description Products Show Technical Features Light transmission: Different colors ranging from 24%-88%. Impact Strength: It is 80 times that of glass board. Anti-ultraviolet radiation: By using 3 ply combined extrusion during its production and coated with high density ultraviolet...

Product Details

Product Description

|

Product Name: |

clear polycarbonate roofing panel |

|

Material: |

100% bayer material or sabic material or customized |

|

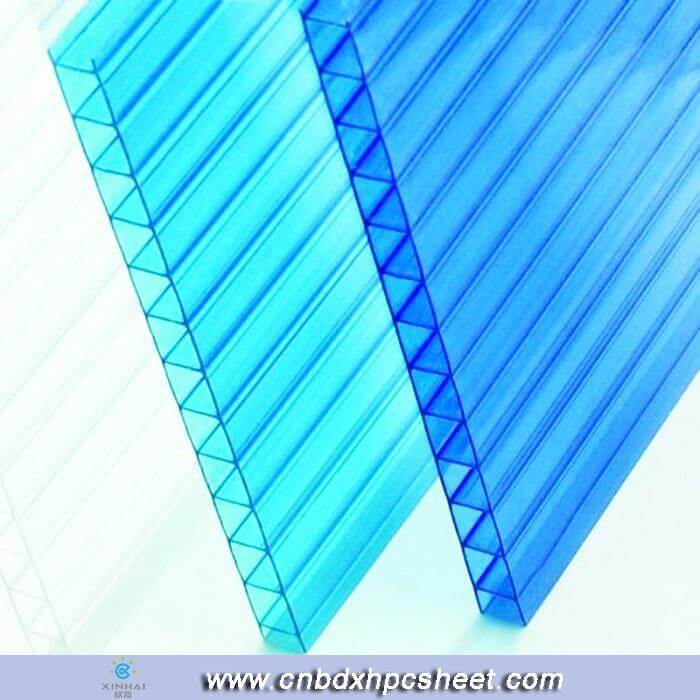

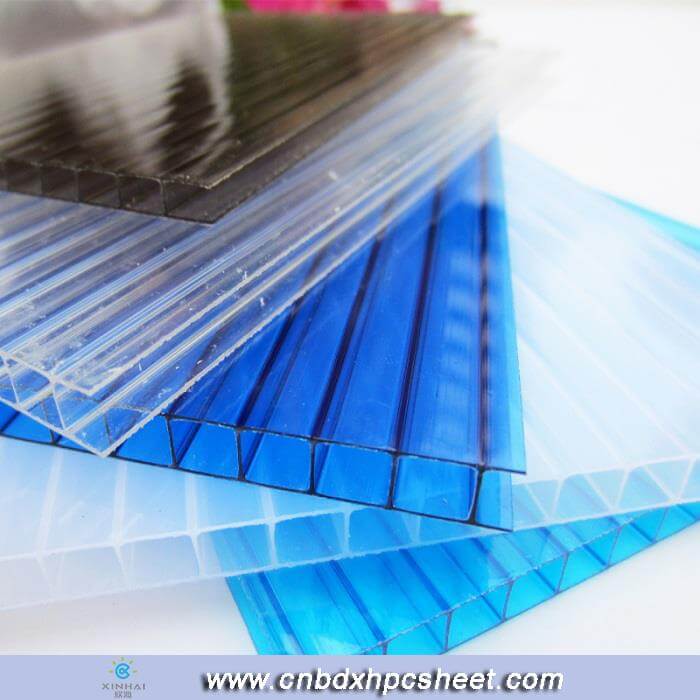

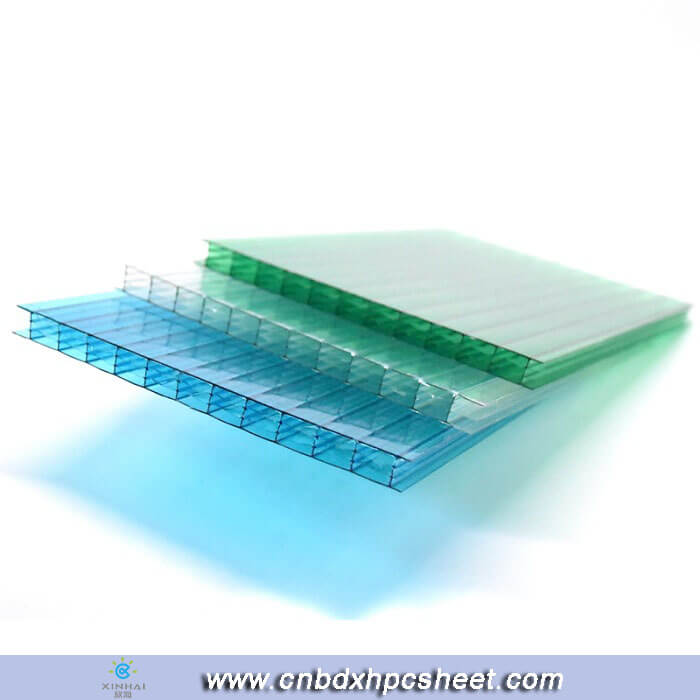

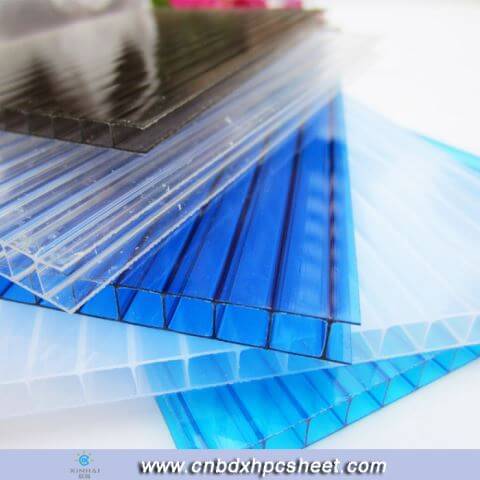

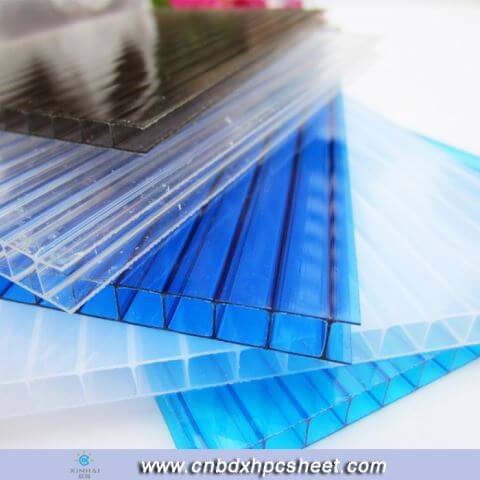

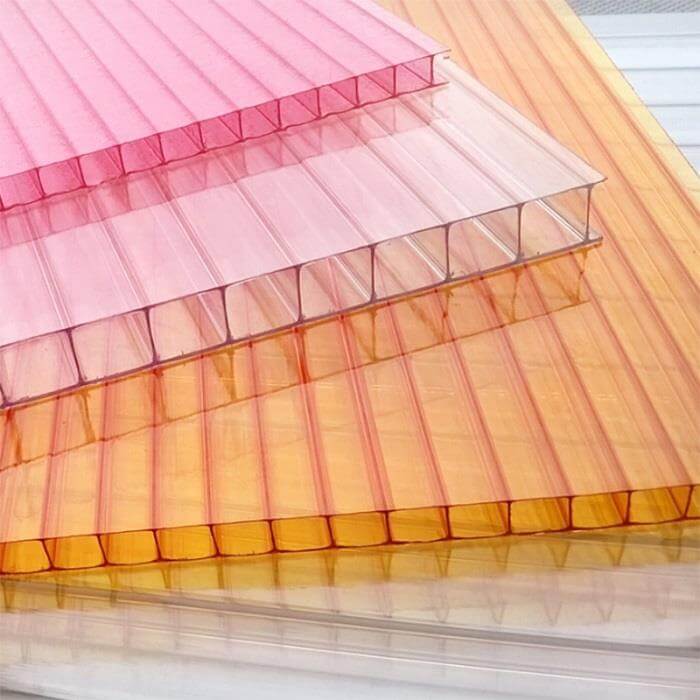

Color: |

Clear, Blue, Lake Blue,Green, Bronze, Opal or Customized |

|

Place of origin: |

Hebei,China |

|

Max Width: |

2100mm |

|

Thickness: |

4mm-20mm,or as your request |

|

Length: |

5800mm,12000mm,11800mm,or can be customized. |

|

Certification: |

ISO9001:2008 |

|

Warranty: |

Usually 10 year's which depends on the models you ordered. |

|

Surface: |

Anti-fog, UV protection |

|

UV thickness: |

50 micron,Franco |

|

Retardant standard: |

Grade B1(GB Standard) |

|

Autoignition Temperature: |

630℃ |

|

Technology: |

Co-extrusion |

|

Sample: |

Free samples could be sent to you for testing. |

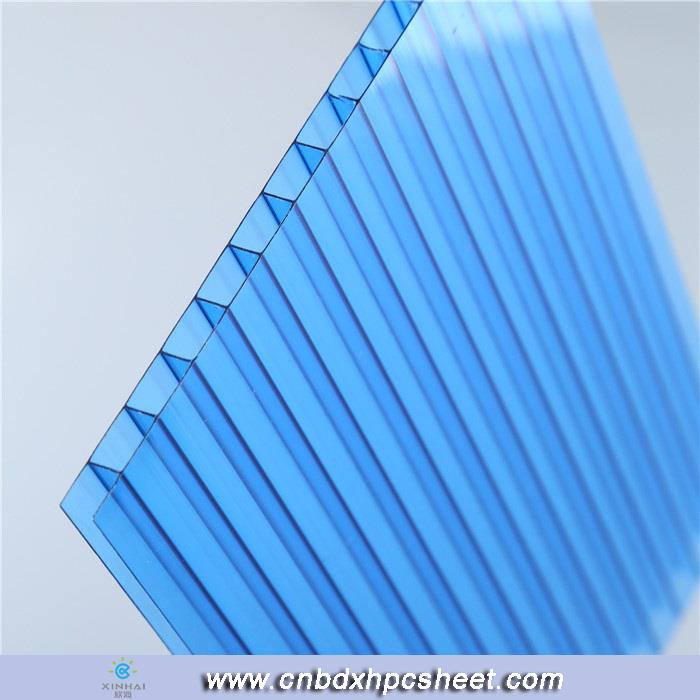

Products Show

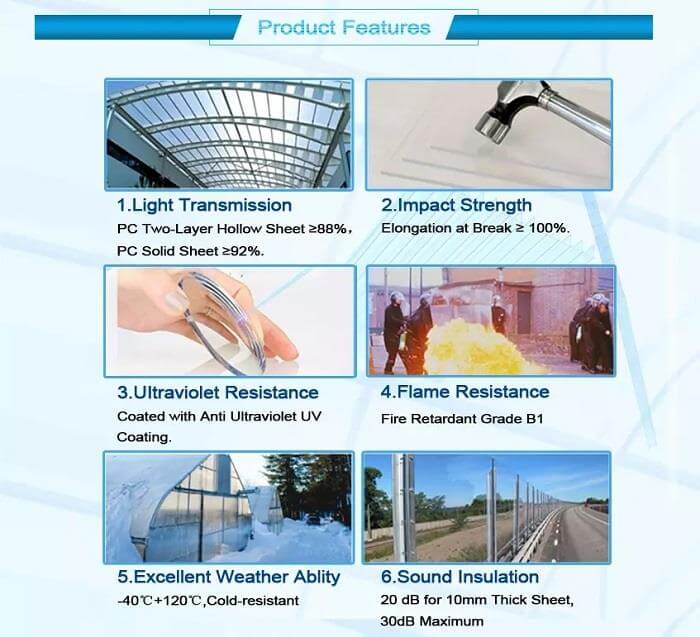

Technical Features

Light transmission: Different colors ranging from 24%-88%.

Impact Strength: It is 80 times that of glass board.

Anti-ultraviolet radiation: By using 3 ply combined extrusion during its production and coated with high density ultraviolet absrbent, it is heat-resistant and has good physical quality under 40-120degree.

Dew-proof: The internal surface of PC sheet won't be dewed under the condition of temperature from 0 degree(outdoor) from 23 degree ( in door) as long as the indoor relative humidity is below 80%.

Sound Proof: With its internal-hollow structure and the good soundproof charactoer, it can reduce noise greatly.

Heat Proof: Heat Conductivity of glass is 1.7 times that of hollow sheet.

Uninflammability: its unimflammability is grade B1.

Light in weight: It is 1/12 that of glass with the same thickness.

Easy to process: It can be cut by normal carpenter tools without special equipment. Its minimum bending radius is 175 times of its thickness. It can be easily shaped to different forms by cooling.

Application

Quality Control

1. Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

2. 100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels

- <

- Previous: Crystal Polycarbonate Sheet Thickness

- Next: Transparent Polycarbonate Sheets

- >